Quote:

Originally Posted by svynx

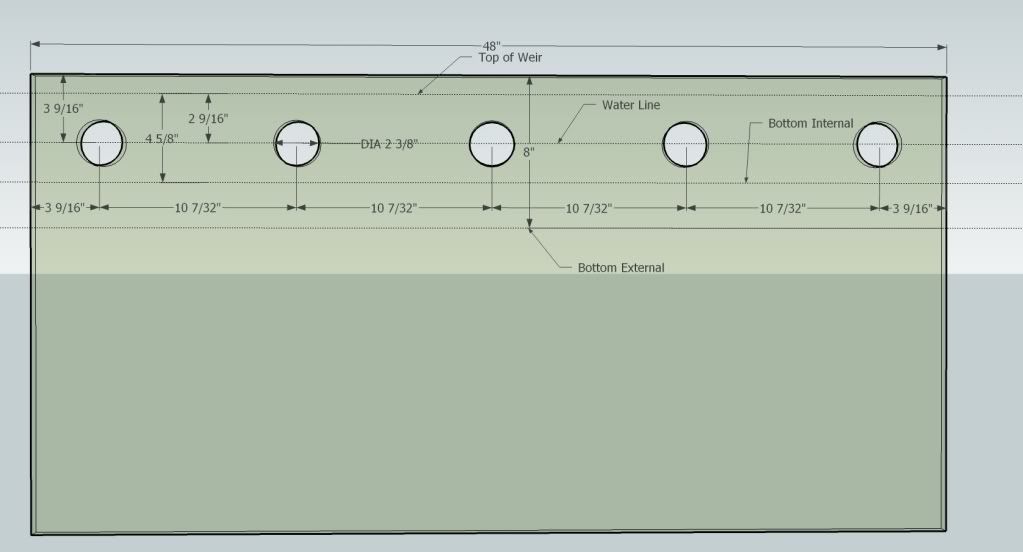

That looks good, and looks like it would work well. Since I'll be doing it on the back panel (48") and using Bean's overflow system, would you recommend drilling more than 2 holes...3 or 4, to aid in getting the flow to the external part?

|

Just to give an indication of the flow rate through an open hole (no bulkhead or plumbing,) a 2 3/8" hole (62mm) with the water level 1" above the top of the hole would be ~1920 gph, and a 3" hole (just did this one in pm) would be ~3060 gph. (rounded off to nearest gpm in the math, and is dependent on several variables including atmospheric pressure, viscosity etc.)

In talking with BeanAnimal about this particular design, some "design criteria" became apparent. (For safety with glass tanks, the holes need to be 1 - 1.5 x the hole diameter down from the top and edges of the glass.)

The internal "weir" would be set (usually) at the bottom of the external rim of the tank (~1" down from the top of the glass) to hide the waterline, and the internal box would extend to below the holes in the back. The external box and standpipes, should be "

situated" on the back so that the water level of the overflow system is at the vertical center of the hole. (the widest part.) The external box needs to extend above/below the holes enough to give you the vertical adjustment to dial the system in. Keeping the water level at or nearest to the centerline of the hole will give you the freest flow, and quietest operation between the internal and external box, while maintaining the surface skimming between the internal/external boxes.

Key factors in this design is freeflow through the holes, and maintaining the surface skimming from internal to external. You don't want bulkheads in the holes, attaching the internal box to the back wall, such as in the gl*******s.com system, rather a blank hole. The bulkheads will inhibit the free flow. Just as the length of a "weir" affects the surface skimming of the DT, so would the number of holes between the internal and external boxes. The number of holes will also make it more freeflowing.

So the simple answer would be 4 holes be better than 2, 6 holes be better than 4. But let's not get too carried away with it.

This should give you a place to start using 5 holes.

A system similar to this is under construction (60",) however the client is out of funds at the moment, (seems to be an epidemic w/associated collateral damage), and it is stalled. So ultimately how many holes there will be is uncertain yet. (or if it will ever be completed)

Jim