|

|

|

|

#3051 | |

|

RC Sponsor

Join Date: Sep 2009

Posts: 14,173

|

Quote:

As for heads for the water change, I would suggest 7518-10. It has stainless rotors and adjustable occlusions. You could go non stainless with a head such as the 7518-60 which also has a stainless head but is made of different plastic. There is also the 7518-00 but I'd go with the 7518-10 if it were me. All those models support a wide range of tubing including LS17. LS17 is the most common and most practical since you can get it from US Plastics via the links in the first page of this thread.

__________________

Director Customer Support Royal Exclusiv USA For All Royal Exclusiv & Bubble King questions please refer to our Sponsor forum: http://www.reefcentral.com/forums/fo...play.php?f=745 Current Tank Info: 480G display mixed reef, 90G sump, 90G refugium, 60G display refugium. Check out my build thread: http://www.reefcentral.com/forums/showthread.php?t=1783476 |

|

|

|

|

|

|

#3052 | |

|

Registered Member

Join Date: Jan 2006

Location: Westminster, CO

Posts: 17,289

|

Quote:

I've posted a design somewhere along the way that could remedy this. Instead of shutting down the AWC by stopping flow on the pump you could put Tees in a high point in both suction lines prior to the pump head that are attached to solenoid valves. When closed they would allow the pump to create a vacuum and operate normally. When open they would inject air into the system and a vacuum wouldn't occur. This does add a failure point but as long as you have a conductivity probe I think the risk is minimal. In the end, I would like to think of this solution as a temporary one while you are waiting on another good deal for another continuous drive. The 3rd head would be transferable to the new pump. Something else to consider. If you don't want continuous you could always go with a more simple economy drive to do the AWC and just plug it straight into your apex and run it 6 hours a day or there about. They aren't as quiet or adjustable flow. You purchase them with a set RPM. I use them for my ATO pumps, they last a very long time but really shouldn't be used in continuous duty. They are often available on the secondary market at a low cost. https://www.coleparmer.com/p/masterf...ed-drives/4509

__________________

Hobby Experience: 9200ish gallons, 26 skimmers, and a handful of Kent Scrapers. Current Tank: Vortech Powered 600G SPS Tank w/ 100gal frag tank & 100g Sump. RK2-RK10 Skimmer. ReefAngel. Radium 20k. |

|

|

|

|

|

|

#3053 | |||

|

Premium Member

Join Date: Sep 2006

Location: Tampa, FL

Posts: 2,252

|

Quote:

Quote:

Quote:

__________________

My skimmate has notes of saffron, and a hint of lilac. |

|||

|

|

|

|

|

#3054 | ||

|

Premium Member

Join Date: Sep 2006

Location: Tampa, FL

Posts: 2,252

|

Quote:

Also, why would I not want to just do a continuous water change (that ran 24/7)? Quote:

Thank you again for your reply and recommendations! My new setup is going to be bullet proof, and this pump(s) will have a huge impact.

__________________

My skimmate has notes of saffron, and a hint of lilac. |

||

|

|

|

|

|

#3055 | |

|

RC Sponsor

Join Date: Sep 2009

Posts: 14,173

|

Quote:

__________________

Director Customer Support Royal Exclusiv USA For All Royal Exclusiv & Bubble King questions please refer to our Sponsor forum: http://www.reefcentral.com/forums/fo...play.php?f=745 Current Tank Info: 480G display mixed reef, 90G sump, 90G refugium, 60G display refugium. Check out my build thread: http://www.reefcentral.com/forums/showthread.php?t=1783476 |

|

|

|

|

|

|

#3056 | ||

|

Premium Member

Join Date: Sep 2006

Location: Tampa, FL

Posts: 2,252

|

Quote:

Quote:

__________________

My skimmate has notes of saffron, and a hint of lilac. |

||

|

|

|

|

|

#3057 | |

|

Premium Member

Join Date: Sep 2006

Location: Tampa, FL

Posts: 2,252

|

Quote:

Thank you so much for your help with this.

__________________

My skimmate has notes of saffron, and a hint of lilac. |

|

|

|

|

|

|

#3058 | |

|

Registered Member

Join Date: Jan 2006

Location: Westminster, CO

Posts: 17,289

|

Quote:

The flow rate varies with pump tube diameter. Adjustable occlusion just means you can match the heads pinch on the tube. If one head pinches less than the other back pressure may cause it not to flow the exact same amount. In the end, I don't think it's absolutely necessary. You'll want to balance the head pressure by tube lengths. Since I had an uneven run I had 25ft of tube coiled up on one side to make the runs even length. Worked great. The pumps push water better than pull so if your pump isn't exactly in the middle you will need to toy with tubing length a bit. Using larger diameter (3/8 vs 1/4) poly tubing to the pump makes a big difference here. Hope that makes sense.

__________________

Hobby Experience: 9200ish gallons, 26 skimmers, and a handful of Kent Scrapers. Current Tank: Vortech Powered 600G SPS Tank w/ 100gal frag tank & 100g Sump. RK2-RK10 Skimmer. ReefAngel. Radium 20k. |

|

|

|

|

|

|

#3059 | |

|

Registered Member

Join Date: Jan 2006

Location: Westminster, CO

Posts: 17,289

|

Quote:

__________________

Hobby Experience: 9200ish gallons, 26 skimmers, and a handful of Kent Scrapers. Current Tank: Vortech Powered 600G SPS Tank w/ 100gal frag tank & 100g Sump. RK2-RK10 Skimmer. ReefAngel. Radium 20k. |

|

|

|

|

|

|

#3060 |

|

Registered Member

Join Date: Oct 2002

Location: Dewitt MI

Posts: 5,051

|

Personally I would keep all 3 functions separate. At least that is what I do. I use one Masterfflex for ATO and one for Calcium reactor. (90 ml/min) I use the Apex Dos pumps for the AWC

__________________

Gary 180 gallon, 40 gallon sump, 3 250 W MH + 4 80W ATI T5's, MTC MVX 36 Skimmer, Apex controller Aquamaxx T-3 CaRx Current Tank Info: A 2 Barred Rabbitfish, Red Head Salon, Yellow/Purple, McMaster Fairy, Possum, 2 Leopard Wrasses, Kole, & Atlantic Blue Tangs, 2 Percula Clown, 3 PJ and 1 Banggai Cardinalfish , Swallowtail, Bellus and Coral Beauty Angels |

|

|

|

|

|

#3061 |

|

Registered Member

Join Date: Nov 2012

Posts: 841

|

Official: Masterflex Calcium Reactor Setup Thread

Thank god for Apex and there Advanced Leak Detectors. Just had a regretful email notification to tell me I had a leak in the Calcium Station (where the CA reactor and CP reside), everything did what it was supposed to and turned off, checked and was expecting a leak on the CA reactor only to find the silicon tubing (the bit thatís being rolled) had split, ran this setup for a few years now and never had tubing split like this, and it was only 2 months old.

Anyway: 1. Did I just get unlucky or is there an issue with the pump head? 2. When the pump heads get old do they damage the tubing more? Time for a replacement head? 3 Am I supposed to lubricator the rollers? Sent from my iPhone using Tapatalk |

|

|

|

|

|

#3062 | |

|

Registered Member

Join Date: Oct 2002

Location: Dewitt MI

Posts: 5,051

|

Quote:

__________________

Gary 180 gallon, 40 gallon sump, 3 250 W MH + 4 80W ATI T5's, MTC MVX 36 Skimmer, Apex controller Aquamaxx T-3 CaRx Current Tank Info: A 2 Barred Rabbitfish, Red Head Salon, Yellow/Purple, McMaster Fairy, Possum, 2 Leopard Wrasses, Kole, & Atlantic Blue Tangs, 2 Percula Clown, 3 PJ and 1 Banggai Cardinalfish , Swallowtail, Bellus and Coral Beauty Angels |

|

|

|

|

|

|

#3063 |

|

Registered Member

Join Date: Nov 2012

Posts: 841

|

Using the Tygon LS17 pharmed tubing, what is recommended in the first post.

I left the unit off, so will check them this weekend more closely. May just spend some money and buy a new pump head Sent from my iPhone using Tapatalk |

|

|

|

|

|

#3064 |

|

Registered Member

Join Date: Jan 2006

Location: Westminster, CO

Posts: 17,289

|

Check the reactor for clogs, it can split like that if the system is building too much pressure.

You can use penetrating grease (not wd40 but an actual penetrating grease) to lube the rollers. Cole-Parmer doesn't actually recommend lube though. Check for bearing wear. It was likely a fluke.

__________________

Hobby Experience: 9200ish gallons, 26 skimmers, and a handful of Kent Scrapers. Current Tank: Vortech Powered 600G SPS Tank w/ 100gal frag tank & 100g Sump. RK2-RK10 Skimmer. ReefAngel. Radium 20k. |

|

|

|

|

|

#3065 |

|

Registered Member

Join Date: Nov 2012

Posts: 841

|

Iím currently using a 7518-00 pump head, the newer model is 7516-00, if the 7518 works with my pump, will the 7516 work also?

Sent from my iPhone using Tapatalk |

|

|

|

|

|

#3066 |

|

Registered Member

Join Date: Oct 2002

Location: Dewitt MI

Posts: 5,051

|

It is not a question of working with the pump, it is a question of working with the LS-17 tubing. Both pumps will work wit the tubing.

__________________

Gary 180 gallon, 40 gallon sump, 3 250 W MH + 4 80W ATI T5's, MTC MVX 36 Skimmer, Apex controller Aquamaxx T-3 CaRx Current Tank Info: A 2 Barred Rabbitfish, Red Head Salon, Yellow/Purple, McMaster Fairy, Possum, 2 Leopard Wrasses, Kole, & Atlantic Blue Tangs, 2 Percula Clown, 3 PJ and 1 Banggai Cardinalfish , Swallowtail, Bellus and Coral Beauty Angels |

|

|

|

|

|

#3067 | |

|

Registered Member

Join Date: Jan 2006

Location: Westminster, CO

Posts: 17,289

|

Quote:

__________________

Hobby Experience: 9200ish gallons, 26 skimmers, and a handful of Kent Scrapers. Current Tank: Vortech Powered 600G SPS Tank w/ 100gal frag tank & 100g Sump. RK2-RK10 Skimmer. ReefAngel. Radium 20k. |

|

|

|

|

|

|

#3068 |

|

Registered Member

Join Date: Nov 2012

Posts: 841

|

Official: Masterflex Calcium Reactor Setup Thread

Is there any way to identify a pump head with a stainless rotor head?

Sent from my iPhone using Tapatalk |

|

|

|

|

|

#3069 | |

|

RC Sponsor

Join Date: Sep 2009

Posts: 14,173

|

Quote:

7518-10 https://www.coleparmer.com/i/masterf...-rotor/0751810 7516-00 In the case of the 7516-00 as well as the 7518-00, they both use cold rolled steel rotors. https://www.coleparmer.com/i/masterf...chterm=7516-00 7518-00 https://www.coleparmer.com/i/masterf...chterm=7518-00

__________________

Director Customer Support Royal Exclusiv USA For All Royal Exclusiv & Bubble King questions please refer to our Sponsor forum: http://www.reefcentral.com/forums/fo...play.php?f=745 Current Tank Info: 480G display mixed reef, 90G sump, 90G refugium, 60G display refugium. Check out my build thread: http://www.reefcentral.com/forums/showthread.php?t=1783476 Last edited by slief; 08/31/2018 at 05:37 PM. |

|

|

|

|

|

|

#3070 |

|

Registered Member

Join Date: Oct 2002

Location: Dewitt MI

Posts: 5,051

|

I recently switched from a Reef Octopus reactor to an Aquamax3. I use a Cole Parmer 7523-80 with a 7518-00 head and an Aquarium Plants regulator. My flow rate is 90ml/min. What is the drawback to colled rolled steel rollers?

With the Reef Octopus the reactor ph held very steady but with the Aquamax the ph continuous swings. Not much but a variance of .03-.04 (see attached graph). The other change was from using ARM media to now a combination of Arm and Newborn. I know the variance is small but I think it is making more difficult to maintain my tank dKH.

__________________

Gary 180 gallon, 40 gallon sump, 3 250 W MH + 4 80W ATI T5's, MTC MVX 36 Skimmer, Apex controller Aquamaxx T-3 CaRx Current Tank Info: A 2 Barred Rabbitfish, Red Head Salon, Yellow/Purple, McMaster Fairy, Possum, 2 Leopard Wrasses, Kole, & Atlantic Blue Tangs, 2 Percula Clown, 3 PJ and 1 Banggai Cardinalfish , Swallowtail, Bellus and Coral Beauty Angels Last edited by hkgar; 09/01/2018 at 02:24 PM. |

|

|

|

|

|

#3071 | |

|

Registered Member

Join Date: Jan 2006

Location: Westminster, CO

Posts: 17,289

|

Just built a little better and survives in our environment better. I wouldn't go out and buy a SS version if I already had a CRS version. Just if you're shopping for a new head...

Quote:

__________________

Hobby Experience: 9200ish gallons, 26 skimmers, and a handful of Kent Scrapers. Current Tank: Vortech Powered 600G SPS Tank w/ 100gal frag tank & 100g Sump. RK2-RK10 Skimmer. ReefAngel. Radium 20k. |

|

|

|

|

|

|

#3072 |

|

Ancient Eskimo Legend

|

Iíve got a GEO 8x18 that has the JG fittings and itís currently just circulating saltwater through it without CO2. For the extremely unhandy folks, can you point me to a diagram of how to hook up the masterflex pump? Any recommendations for the masterflex pump these days? Thanks

__________________

The wind blew, the chit flew, and then they came two by two. ~~~~~~~~~~~~~~ Current Tank Info: 375g Tanganyikan Tank & 470g mixed reef |

|

|

|

|

|

#3073 | |

|

Registered Member

Join Date: Dec 2003

Location: Milwaukee, WI

Posts: 1,161

|

Quote:

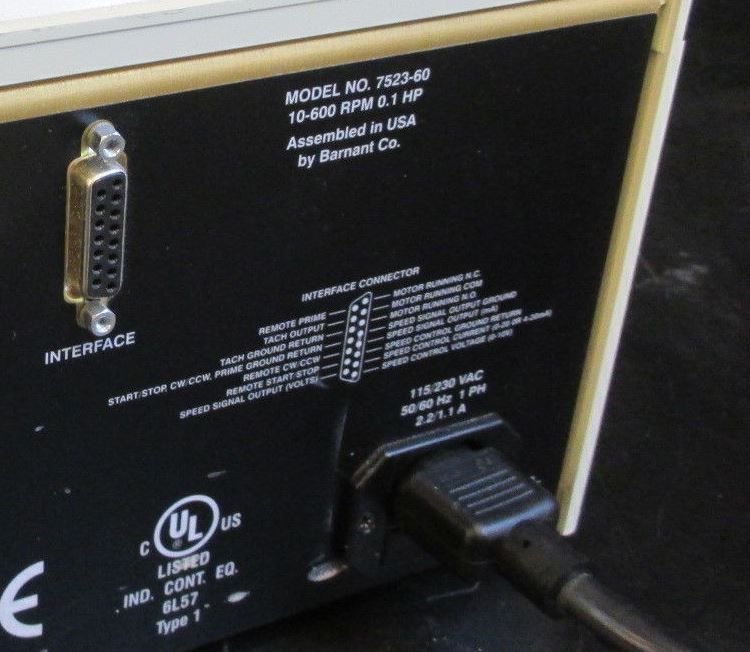

*Also, in the user manual, it says I can control it with RS232 / Serial, so easily could be controlled with an Arduino for home users. Full control could then be granted, giving you access to see the motor speed/direction, change speed/direction, start/stop, prime. But for most of our usage needs, I think adding the 0-10V from the apex to throttle up/down will be enough. APEX could only send 0-10V for speed. You can set in device to make 0V = 0ml/minute and 10V to = X ml/min, so you can choose max flow to be 100ml/min for instance, if you wanted to limit max speed via remote control.

__________________

300G SPS reef build in progress Current Tank Info: 300G reef under construction Last edited by zachtos; 09/10/2018 at 11:44 AM. Reason: read the manual |

|

|

|

|

|

|

#3074 | |

|

Registered Member

Join Date: Dec 2003

Location: Milwaukee, WI

Posts: 1,161

|

Quote:

The manual says STOP/START , DIRECTONCW/CCW, PRIM via contact closure... so I THINK that means if you short the +/- terminal for START/STOP, then the motor will START in shorted, and STOP if opened... same for prime, same for direction... that can be done with a paperclip or solder on the back of your connector... Someone let me know, this is easy to test. Put 10V on the 10V pins, then short the start/stop pins and it should go. You need to download the manual and read how to get into remote control mode.

__________________

300G SPS reef build in progress Current Tank Info: 300G reef under construction Last edited by zachtos; 09/10/2018 at 11:59 AM. |

|

|

|

|

|

|

#3075 | |

|

Registered Member

Join Date: Jan 2006

Location: Westminster, CO

Posts: 17,289

|

Quote:

Setting the max ml/min in the controller is smart.

__________________

Hobby Experience: 9200ish gallons, 26 skimmers, and a handful of Kent Scrapers. Current Tank: Vortech Powered 600G SPS Tank w/ 100gal frag tank & 100g Sump. RK2-RK10 Skimmer. ReefAngel. Radium 20k. |

|

|

|

|

|

| Thread Tools | |

|

|